In September of 2019 when I was in Boston and walking around downtown Boston, street photographing, I came across some places which were cordoned off with blue street curtains as high as 10 ft. I could find such sites at several places in Boston, and therefore I just asked one of the local-looking passer-by as to what’s with these cordoned areas. He said, “The leftover work from the Big Dig is now being finally completed using Small Digs”. Apparently he thought he said something funny assuming that I would know the significance of what he said and looked at me expectantly to see me laugh or something, but well I was as clueless as a door knob, at that point of time. The lightly exasperated Passer-by just walked on shaking his head. It was only when I got back to the B n B on an Island close to Boston called Winthrop that I poured myself a large mug of ‘Samuel Adams” and searched for “Big Dig” and was surprised to see what I came to know. A project that was very complex, no doubt, but also a project that was managed in such a horrendous manner, replete with complete lack of risk management and reeking of criminal corruption, that this project finds it’s place into the PM-Pulse blogs on “Worst Projects” in the world.

A little bit of history.

Boston is one of the oldest cities of USA. It had always been wealthy, congested and bustling with life. The city planning was done at a time when there were no automobiles, just carriages, and hence an entire downtown sprang up which was not planned for many automotive. But, just all other US cities, Boston too started to choke under the onslaught of vehicular traffic.

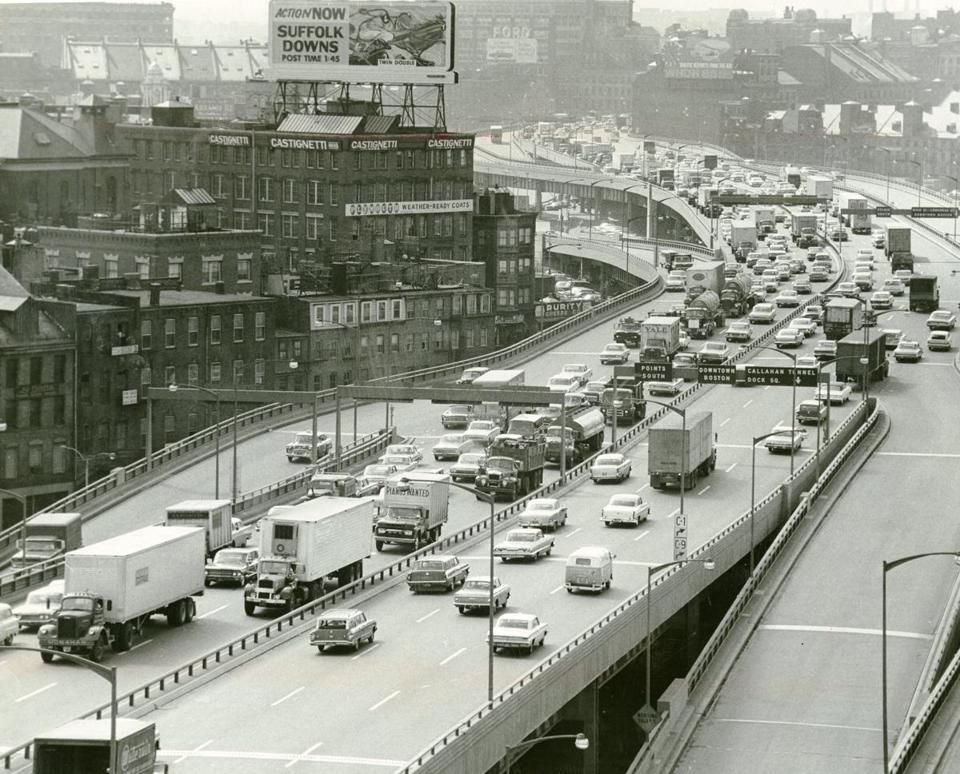

In 1960s, to ease the traffic conditions, an elevated expressway was constructed to make it easier for people to drive. This expressway just divided the entire downtown into two. It had the capacity for 75,000 vehicles per day but by late 1970s the traffic had already reached over 200,000 vehicles per day leading to traffic jams that were sometimes a day long. This expressway was termed as the “Central Artery”.

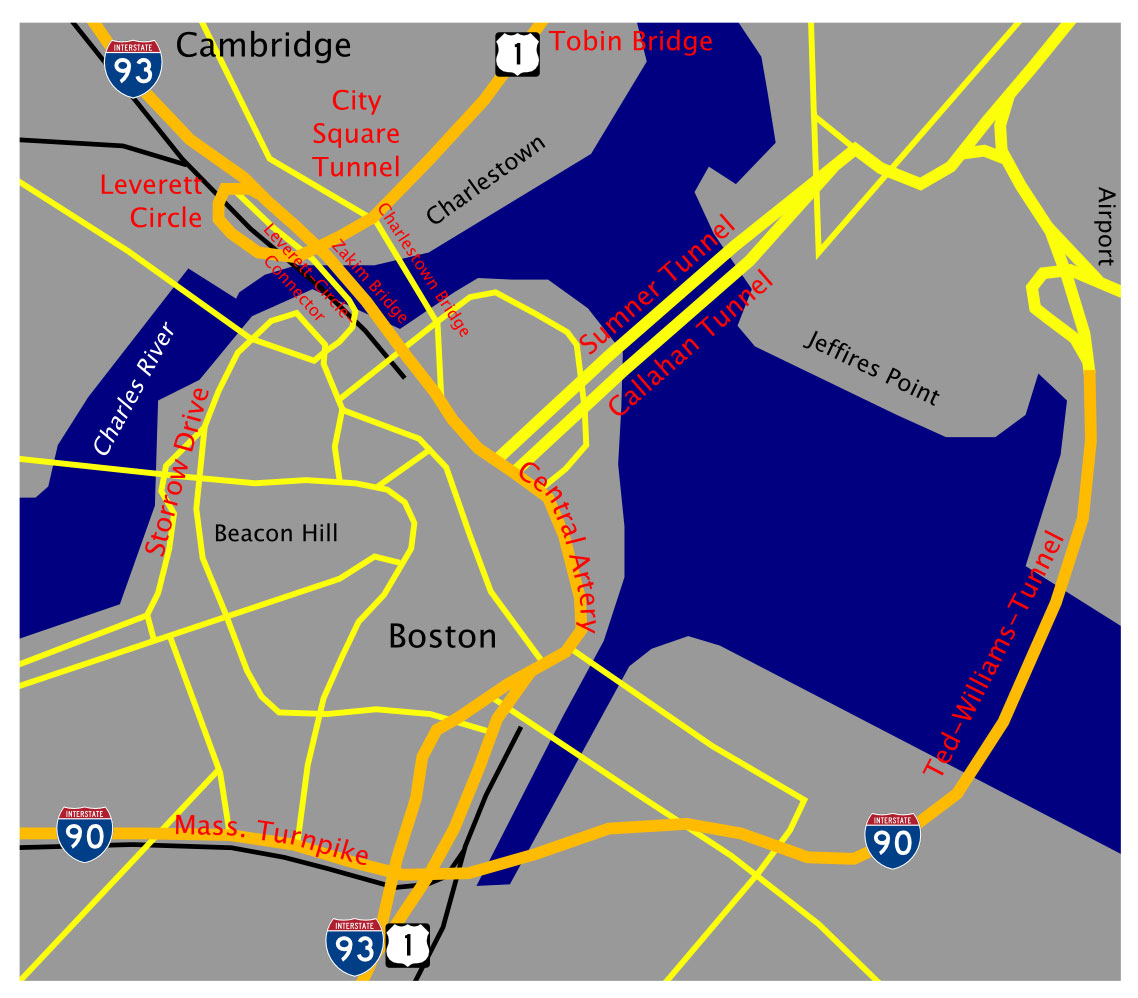

Fred Salvucci, an MIT graduate, who worked for the Boston Transportation Department, was given the task to rework the road system of Boston. He Took a decade to make the plan ready and sink most of the “Central Artery” underground and to create a new tunnel under the Boston Harbour to connect the south Boston to the Airport and also to construct a new wider bridge over river Charles. This project was initially called the “Central Artery / Tunnel Project” or the CA/T project, but over time, the unimaginative simplicity of people of Boston, soon termed it as the “Big Dig” project.

By 1980s Salvucci, who had become the Transportation Secretary and also hugely politically ambitious, decided it was time to put his vision into practice and started gathering a lot of public support by directly reaching out to them. With this he overpowered the local Boston authorities to give him the mandate to put his vision to work. For funding however he had to go to Washington to obtain federal funding. Ronald Regan, the then president of USA, vetoed it twice.

Salvucci, who had already put into motion the environmental studies and having promised some big construction companies a lot of work, got the political and business muscles to arm-twist the Congress to grant funding for this project. The congress overturned the Presidential Veto by just one vote. A vote that would prove to be worth USD 22 Billion. Thus started the most ambitious infrastructure project in the history of US which also became one of the most ill planned, executed and managed projects in the world.

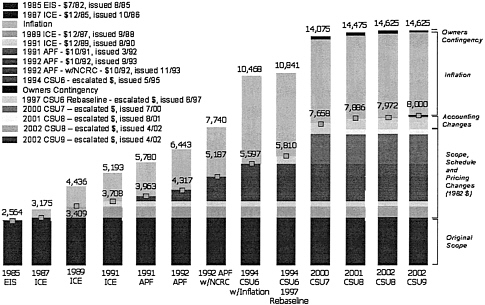

The project planning officially started in 1982 with the first step being the study of “Environmental Impact” and to garner the support of the local heavy-weight business community to understand the entire scope of the project. Project estimation was done and it was estimated that the project would cost USD2.8 billion.

From 1983 till 1990 there was hardly any serious or practical planning done, because this project had already become political and almost every bit of time by the key stakeholders was only utilized for getting hold of the Federal funds from the central government. They finally managed to procure that funding by 1990 and with less than 4 months of planning and vendor selection, the project was officially kicked off in 1991.

The moment the project entered construction phase, it was stopped immediately. There were fears that the “Big Dig” would release some deadly toxins into the Boston air and that an empire of Rats and Rodents, whose adobes would be destroyed due to the excavation activities, would end up roaming the streets of Boston, making it like the “Fabled Hamlin” like situation. This study, almost a useless one at that, stopped work till 1994.

But by 1994, because of inflation, the vendors stopped work till price revision was done. This raised the budget from USD2.8 Billion to USD 5.8 Billion.

In terms of planning a very confusing and overcomplicated reporting of engineers and project managers were created that was more political than practical. Certain powerful vendors were given almost free hand in designing and their phase planning. The intention was that this way the work would get done faster and the work would get completed by 1998. This kind of autonomous planning and confusing communication plan along with run-away corruption and greed would result into one of the worst project nightmares in the history of the project world.

In 1991 the first set of work that started was the construction of the trench on the sea bed from south Boston to the island where Logan International airport existed. This could continue while the other on-ground was halted for additional study till 1994.

The idea was to construct the 8 lane tunnel by first cutting a trench on the sea bed then placing the prefabricated sections of the tunnel encased in steel on to the trench, then welding the tunnel sections together and then finally covering up the tunnel with the excavation material removed from the trench. The tunnel sections, totalling 12 in numbers, were being constructed in Baltimore, Maryland. They were to be shipped up north to the Boston harbour and then sunk into place through precision guidance.

However when the steel sections arrived in the Boston Harbour, there was so much of politically motivated hype that these steel sections were not measured against final specifications. This was also not done at the Baltimore construction site. With a lot of fanfare the sinking and placing of the steel sections were lowered into the trench and welded together, only to realize that the entire welded tunnel that is already sunk under 100 meters of water is 5 ft short.

However because of the huge political whiplash that could take place if this information was made public, they simply tried to extend the Airport side land tunnel to meet the submerged steel sections. What it seems is that all of the people in the tunnel works forgot the simple rule, “Measure Twice – Cut Once”. But despite all these issues, the tunnel was the only construction that happened relatively well and without much hiccups. The tunnel was officially completed on December 15th, 1995.

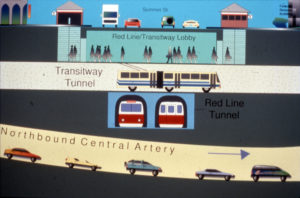

This construction was still not over. This tunnel had to be now connected to the interstate highway network that, among other things, connected to the Logan International Airport. And this is where the problems started. Instead of making an elevated highway, Fred Salvucci decided to continue the tunnel inland as well to ensure that no Bostonian is disturbed. This meant tunnelling under another water body and several lines of some of the oldest underground rail system. The tunnelling would have to be done under the pre-existing and in use heavy rail system, without a allowing for any caving-in to the rail tunnel. This further delayed the project immensely.

Construction was going on in way that the work would begin based on a very basic planning and then the engineers would get to work, who would then report issues and problems as the work progressed and the project manager would then work with the engineering team to plan only to the extent of removing the problem. The plan was never forward looking, nor was it learning from its past mistakes and nor was it conducting any kind of extensive risk management. Everyone of the project managers were more interested in keeping up appearances and creating an illusion of “all is of well” with the project.

When the underground tunnel was being dug under the “Central Artery” (that 6 lane elevated highway) there was hardly any “Seismic Imaging” was done to see what lies beneath. Seismic Imaging is a very simple technology and very old method used for excavation. A bit of gun-powder is fired through a tube facing downwards into the earth and the sound waves received back once they bounce off stuff under the earth actually creates a proper 2 D image telling you very clearly what lies below and at what depth. In their political hurry they did not even do that and hence the tunnelling ended up cutting up phone lines, electrical lines, sewer lines, and once even came across an underground historical site that had historically significant artefacts which got the construction stopped for over 8 months to allow the historians and archaeological professionals to remove the findings and relocate them safely. While all this happened all the wages for the assigned waiting labour and machinery was being billed and the costs of the project kept rising.

Keith Sibly, one of the Project Managers, was facing a lot of local resident flake for the immense sounds that they were making while working, digging, transporting, hammering and excavating 24/7 right in the middle of the city. The residents were almost up in arms protesting the sound and vibrations that kept them awake all night which affected their health. Just Imagine that this basic risk management was not done and no mitigation plan was put in place to prevent this local residential issue. The project team kept ignoring the complaints of the residents for 3 yrs and continued in their work, which itself was progressing at a snail’s pace, till they could not ignore it any further. They were forced to cut down work at night and also reduce noise during day. The new mayor also created regulations about the dust particles in the air due to digging. This all lead to change the design as well as change the machinery. Not only this, thousands of square meters of awnings and coverings had to be procured to prevent the dust from escaping. However this “Post Problem Resolution” was referred to as “Risk Mitigation” by Mark Lewis, Project Director and faced a lot of flake from press and every other project professionals. Imagine a project director of such a significant project who has no clue about what is risk management and is calling “Excessively costly workarounds to somehow get over the issues and problems” as “Risk Mitigation”. And all this while the project costs continued to balloon and expand. As part of the “So called Mitigation” process, in August 2002 the unfinished tunnel under the Central Artery was opened to Boston Public to make them see what was happening.

This entailed huge additional costs just for this event because for this event all rubble, machinery, tools and goods had to be removed, security arrangements made, additional staff deployed to keep the Boston Public Safe, while they toured this unfinished tunnel. The expectation that Mark Lewis had from this event was that when the public saw for themselves what was being done, they will have appreciation for the work and effort and become more supportive of the construction work. However this did not work well entirely. While many liked the effort but many also complained about how little has been done in so long a time.

All this style of execution kept on pumping the project cost upwards. Several accountants and treasury guys were caught cheating and skipping audits and had to be fired under criminal investigations, with none of them ever getting charged with any wrongdoing.

The planning team and the engineering team were so far removed from the actual working team that several issues kept on cropping up. In one case one of the construction teams drove a pile into the Charles River bed for the construction of the new suspension bridge, actually drove it through a network of freight tunnels made earlier. The construction team was working without any map of what lay beneath. This created a huge municipal disaster that set the project back by several years and half a billion in repairs and compensations.

This was not the only incident. Hardly any of the old drawings were referred to understand the layout of the gas pipes, electrical cables, telephone cables etc. The construction team was constantly cutting through power cables, gas lines and telephone lines and once, even through the sewage line causing serious health and hygiene issue. Every time such an event would happen, someone would get fired, the problem would be addressed by investing more money and time and labour and no learning passed on whatsoever. Meanwhile the project kept on getting delayed.

Between 2004 and 2007 there were guided walking tours for tourists through the various sections of the tunnels, they were just as important to tourists, as a monument of disaster as the other historical monuments that adorn every part of the city.

Soon another problem became apparent. It seems that throughout the construction phase, the vendors and suppliers had been shipping and applying sub-standard material. This was creating havoc. The construction teams had to tend to thousands of leaks in just the tunnel alone. The concrete would crumble even after curing, during winters much of the underground roads would develop cracks due to the frozen soil around them and so on.

Due to the extensive traffic that was to move underground a lot of dangers were predicted from suffocation, to build up of dangerous gases, and the cascading effect of an accident or explosion inside the tunnel (something that was highlighted in the movie called “Daylight” which was based on the Manhattan Tunnel Explosion) it was found that the sensors, cameras and other monitoring equipment were just not sufficient and their quantity as well as their quality were increased. This resulted in further ballooning not only the project costs but also the post-handover maintenance and running costs. As I write this blog, there are close to 65,000 sensors, monitors, cameras and other devices in operation within the two tunnels of this project.

This criminal finding resulted in a lot of backtracking of the project, repairs, almost constant maintenance and settlement of unending claims. In one case, the construction teams had to provide 24 miles of power cabling through alternate routes for 31 energy companies because they were fed up with power disruptions due to the Big Dig constantly cutting through those power lines. One of the worst cases was the substandard watertight seals giving way to Atlantic water entering the tunnel and completely flooding it. This ruined all construction equipment within the tunnel and millions of dollars of losses. This happened in 2001.

The project is now estimated to complete at USD 15 Billion not counting the interest on loans as well as the claims to be paid. Boston Globe correctly estimated the Estimate to Completion to be USD 22 Billion. And that estimate has now be proven to be correct.

There is no doubt that some of the most ingenious methods were used for construction. Things so ingenious that one could make movies around each of those methods. However none of that was planned in advance. Each of the solutions were developed after the problem was encountered. I mean, in certain cases even a soil survey was not done to understand the soil composition and later ingenious methods were devised, while the work stood still for months, literally in the middle of actual construction. This was the main reason why the project became so obnoxiously expensive and delayed.

When I see so many US based documentary movies talking about the reason why the project was so expensive was due to the excavation that they had to do underground and underwater. That may be the case, but let us understand that some of the oldest underwater tunnels in the world are in Boston anyway. They had all the lessons that they wanted to learn including the availability of soil samples from all over Boston. Come to think of it, the discovery channel was trying to say that one of the most challenging part of the project was creating a tunnel underwater but just above another older, in use, underwater train tunnel that was made in 1914. Boston did this in 1914 in record time with hardly any modern equipment let alone the satellite guided laser positioning system that were used for the Boston Big Dig and yet horribly delayed and unbelievably expensive. The problem is Fred Salvucci wanted to create a legacy so badly that he just did not look into the wealth of information that just lay around him in the very building he operated from.

In July 2006 a lady who was driving her car through one of the tunnels, got crushed by a huge steel panel from the roof of the tunnel that fell on her car. Killing her instantly. Gruesome as the tragedy may be, what came to light that the steel panel was “Glued In” and not bolted to the ceiling of the tunnel roof. This opened up another round of “Can of worms”, further repairs, immense compensations, public hearings and loss of face by the local transportation department.

Even till date, there has not been a single month when the tunnels have not turned up any major issue, like leakages, cracks, falling of the lighting fixtures, incomplete fittings and so on. It has been unofficially estimated that the cost of these constant repairs and replacements would cost nearly as much as the project itself.

However, I cannot help but mention the absolute amazing beautification of the place where the original Central Artery elevated expressway stood. That entire stretch is a string of gardens, lakes, natural zones and just an absolute treat to walk around. And for a person like me, who loves to walk, that place is now etched into my memory.

But I am also a rather accomplished project management expert and from that standpoint this project was one of the most ill managed project on the planet.

Everything came to fore when Seattle also wanted to do a similar thing on a lot smaller scale and wanted to make sure that the lessons from the “Boston Big Dig” project were not repeated, but well, they too had very interesting delays and reasons for cost escalations. But then that is material for another blog. J

By all means this project was a “Big Dig”, not necessarily in terms of the excavation, but definitely in terms of the big financial hole it has ended up creating in Federal as well as State’s funds and budgets.

Some of the most important lessons from this project can be listed as under: -

-

No matter how politically motivated any project work is, it just cannot replace professional category project management.

-

Extensive experience in a specific domain does not necessarily translate into effective project management. Professionals who have spent decades in the operations side any domain would not become a “Natural Choice’ for project management in that same domain. Project Management is a completely different beast in itself and is completely different from Operations Management.

-

For large projects specifically being conducted within a large city, Risk Management and Simulation are the most important aspects of project planning. Working hard is not the same as working smart. Such projects must never have a fast start. These projects must never start in a simultaneous manner where lessons cannot be learnt from part of the project into another.

-

Just putting too many managers and engineers and asking them to take decisions based on the problems they face is not a substitute to effective granular planning. In absence of a proper planning, this kind of local empowerment becomes chaos and a hot bed of miscommunications and rumours.

-

For large projects an independent cost estimation must be done before getting into the politics of federal funding game.

-

The project managers must keep preventing scope creep.

-

Issue management and Problem resolution after they have happened is not really “Risk Management”.

-

When the project has people from different countries and cultures, the communication plan has to be even more stringent.

-

The stakeholder management must be done excessively stringently and comprehensively as early in the project as possible. No matter how much of stakeholder reach-out is done towards the execution phase of the project, it would provide any benefit to the project.

-

Large Projects must have a very effective project tracking system. A tracking system that not only checks the progress but also does effective forecasts to understand how much we would end up spending once the project is completed. These forecasts help us take better preventive decision making.

-

Project planning and choice of design for such large infrastructure projects must also take into account the “Life-cycle costing” of the entire project as well. There are many large projects which have become white elephant to maintain after the project has been handed over.

=================================================================================================