One of the beautiful North Eastern States of India is called Assam.Through Assam flows the mighty river called the Brahmaputra. This river is so huge and volatile that it has been termed as the “Flowing Ocean” by the local population. It floods every year and decimates villages and towns on its banks. The level rises by over 30 feet during monsoon and brings with it millions of tons of silt.

The two important towns of Assam, Dibrugarh and Dhemaji, are situated on opposite sides of this river. They have always been an important trade and commute route for the people of Assam. The earlier movement of goods and passengers were either through a very long railway route that would take 34 hrs to commute from one town to another in either direction or it would be done through the private owned local ferries and barges that would cross this volatile river. In that past there has been several cases where life and goods perished in river due to ill maintained boats or due to the acts of the river itself.

Though the demand for a bridge on this important section had been in place since 1960s it was only in 1997 that the then PM of India, H D Deva Gowda, laid the foundation stone for this bridge. However due to political unrest and change in government, absolutely no work (not even designing) was done. On 21st April 2002 the then PM of India, Mr Vajpayee, officially started the construction of this important bridge. A very well thought out and well estimated budget of INR1,767 Crores (USD 250 Millions approximately) was earmarked for this project. The main construction was to be done by Indian Railway Engineering department as well as the Hindustan Construction Company (HCC).

The original business case for this project by the BJP government was as under:

-

Create a direct connectivity to 5 Million citizens in that region of Assam and the neighbouring state of Arunachal Pradesh.

-

Reduce the commutation time between Dibrugarh and Dhemaji from 34 hrs to just 3 hrs.

-

Increase the trade and investment opportunities in that area.

-

That area being close to the China border, this infrastructure to be also used for swift deployment of armed forces, mechanised infantry, armed cores like Tank Divisions and also for providing logistic support to the armed forces.

-

To help extend the medical facility to the people of that area.

-

To reduce the need for ferries that were some of the leading causes of river based casualties in that region.

The BJP government under the stewardship of Mr Vajpayee selected HCC to be the main contractor for this bridge because they had the experience to build two bridges on the mighty river of Brahmaputra in the past.

The design was immediately made for a double decker bridge with railway lines (2 sets) on the lower bridge and a 3 lane road on the upper deck. The total length of the bridge was supposed to be 4.94 km and when completed the bridge would be the longest in India and the 2nd longest in Asia. They also needed approach roads that would stretch about 100 kms in both sides of the bridge to provide the connectivity to the nearest key towns.

Work started in earnest. There were supposed to be 42 pillars that would support the bridge over the river. These pillars were to be constructed first. Since the river was very volatile each of the pillars would be built in a well that would be placed in the river to circle off an area and water pumped out of it, made dry, and construction of pillars would happen in that dried up well, while the river keeps flowing around it. This would prevent the need for diverting the river to reduce the flow and minimize ecological damage due to construction.

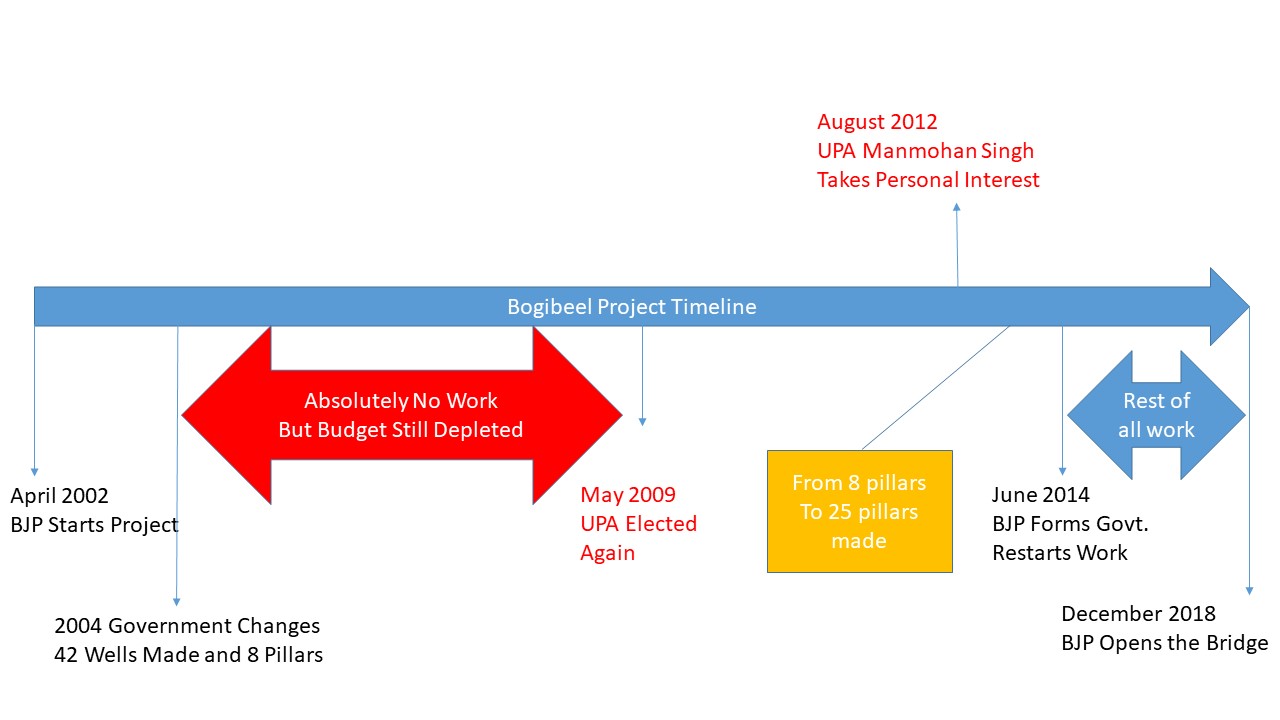

By the time all the 42 wells were made and dried out, and work started for about 8 Pillars, the government in the centre changed hands in 2004 and the new coalition UPA came to power. Almost instantly this project was put on hold. For the next 5 yrs during the UPA government’s term nothing moved forward. When the UPA was elected again at the centre, due to pressure from the local political party at Assam, which was also Congress, the then PM Manmohan Singh designated this project as a National Project.

Still nothing moved.

Hence for 7 yrs absolutely nothing moved forward in the project. Not even a truckload of sand.

When the Mr Manmohan Singh personally got involved in the project, his aid in planning commission informed that the entire budget which was allocated initially was completely utilized. And a new budget would be needed to continue work. Hence the two dry wells for pillars were made at a cost of INR1,767 Crores even though they were made in just 3 months, but kept in abeyance for 7 yrs. I am sure these two dry-wells would be the costliest in the world. Thanks to abject corruption by UPA.

By this time the UPA was under international and internal attack for massive corruption in almost every walk of their governance. Out of frustration as well as with a will to show some credible work just 2 yrs before the next elections the PM Manmohan Singh instituted a committee to find out how much would it cost to complete the work on the Bogibeel bridge. The new estimate came out to be INR 3,593 Crores. Which was approved and the work started. Though the budget was approved very little money was actually finding its way to the contractors. Hence though the work started it was slow and constantly stuck in bureaucracy. Work progressed so slow that soon the monsoon started and the work had to be stopped again.

Finally in April 2014, one of the leading newspapers reported that about 25 pillars out of the 42 pillars were made and some of these 25 pillars were also not fully constructed.

In May 2014 the government changed, and BJP, Led by PM Modi, took over charge of the nation. One of his dreams was to finish the work started by his Mentor Mr Vajpayee. Almost immediately he sacked the earlier planning committee and instituted a more autonomous body of professionals under the minister Mr Gadkari, to find out how much of that inflated budget was left and if that would be sufficient to finish the project. He also wanted the project to be done in just 3 yrs time. It came to light that a major portion of the inflated budget during UPA times had vanished and a fresh funding of INR600 crores would be needed. This was granted and the work started immediately.

The Ministry along with HCC and Indian Railways conducted a detailed study for the risks involved as well as the cost effective ways to speed up this project and finish it under very tight timelines and with a tighter budget.

Some of the risks that came to light were as under: -

-

This area was prone to flash floods and twice in the past had flooded and eroded the banks of the river where bridge material was kept thus resulting in some losses.

-

This area also suffered severely from seismic activities which meant that the bridge needs to be both strong as well as flexible to absorb the shock waves.

-

The earlier design of using traditional construction would allow for faster construction.

-

Since the bridge was very long, sections of the bridge had to be taken on barges on the river and pushed up between the pillars through a combination of hydraulic cranes and elevators. However this presented some serious challenges. The volume of the river changes almost daily, hence every day the pulling and pushing capacity of the cranes and elevators would have to be recalibrated to lift / push the bridge sections from the floating barges to the pillars. Though this was possible but would end up taking even more time.

-

The local economy was getting affected due to the bridge because the bridge would make the ferries and boats irrelevant. The affected party were trying to scuttle the bridge building works. This situation was getting more and more militant by the day.

-

Due to increased international tension with China, India needed new Airforce bases and also some temporary emergency bases as well.

After a long set of deliberations, cost/Benefit analysis and out of the box thinking the following plan was made, going forward:

-

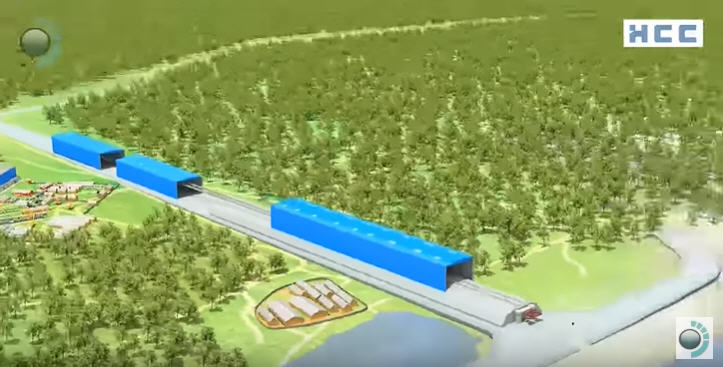

The entire sections of the bridge to be placed over the pillars would be assembled in an assembly line format. This assembly line was built right on the railway tracks so that the supply of raw material could be lifted directly from the train racks and placed on assembly racks with a short move of a magnetic crane.

-

There would be three assembly and fabrication units and all of them constructed as sheds over that same railway line so that the partially finished products from one assembly section would be simply pushed to the next assembly section using the same railway track. This would save immense costs in local transportation that would involve making local infrastructure like roads and hiring more trucks and labour.

3. The original design of bridge sections was changed into a “Fully Welded” sections. This would have a higher initial cost but would speed up the work and also make the sections very strong and almost immune to any kind of maintenance work (something which is routinely expensive in sections made from bolts and rivets). This was one of the best examples of Value Engineering that I have seen in a large infrastructure project. This new design resulted in this bridge to be the first and the only “Fully Welded” steel bridge which has not used any rivets a bolts in their construction.

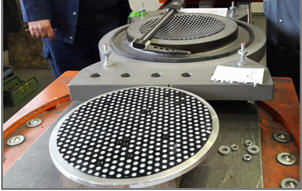

4. Each of the section bases (that would rest on the pillars) were made from large platforms that would have groves holding high calibre ball-bearings. This would not only allow the bridge sections to withstand any kind of earthquakes without breaking the sections. Ball bearings would give the stability as well as flexibility for allowing the sections to flex during seismic activities. Not only this, these bases could also handle the vibrations created and the pressure created by movement of a full division of tanks across the bridge during military movements.

-

The welding was done using automated welding machines that would cling to the surface of the section to weld every nook and cranny. This saved a lot of money. In most cases where such massive scale welding is required the entire section has to be rotated to allow welding arms to weld the joints properly. The amount of money that would be used to have mechanical and hydraulic “Jig” to rotate steel sections weighing in excess of 200 to 500 tons would be enormously expensive to build and maintain. Instead smaller welding machines which would have magnetic rales were used to move around the sections welding automatically, just like how a spider climbs up and all around.

-

A brilliant level “Agile” testing was done through a separate team of testers and Quality Auditors. They were just as many in numbers as the number of construction engineers. For every weld, for every joint, for every assembly the team would constantly test, audit and approve or otherwise, every aspect of the work at the production stage itself. The metrics were kept very tight giving not even microscopic levels of deviations. This idea was the most instrumental in speeding up the assembly sections (a total of 44 sections steel sections).

-

However the most brilliant part was the way the section was placed on to the pillars. Not a single boat or barge was used and hence the entire risk of adjusting elevator heights due to change in river levels was completely avoided. Since the 3 assembly units were in one single row right on the railway track, a track that would eventually be on the bridge itself, each of the sections that was built in the final assembly unit was “Pushed” on to the pillars. The first section was placed on the first set of pillar. The moment the second section was ready they just attached that section to the back of the previously placed section and then push the entire assembly to the next pillar. This system allowed immunity of work from elements of nature. And the work progressed at record breaking speeds. This way all the sections were “Pushed” on to the pillars like train being pushed from behind.

8. Huge barriers were made on both sides of the river to prevent any kind of erosion during seasonal flooding in the river and thus preventing the roads and maintenance sheds on the banks of the rivers to be washed away. These walls were made high enough to provide protection to the farms and agricultural lands nearby as well.

9. The minister Gadkari himself got involved with the local ferry and boat owners to make alternate business arrangements for them. Some of them were given loans to buy busses and run busses point to point from Debrugarh to the other side of the towns. Some were even given local security related work and so on. The completely eliminated any kind of resistance and generated a lot of positivity for the bride work itself.

10. The design of the bridge housing the railway tracks as well as the road in the upper deck were redesigned so that the roads could be used for emergency landing and take offs for fighter aircrafts. The side railings have been kept in a way that would not prevent most of the fighter aircrafts from landing and taking off there. Besides this, special concealed holes have been made in the upper deck to allow fuel pipes through from lower (railway deck) to the road deck to allow, in times of war, to allow fighter aircrafts to land there and get refuelled and re-armed by the supplies brought from the railway to the deck below. Thus increasing the nation’s ops readiness several notches.

11. The bridges have also been reinforced with redundant material to ensure that it can withstand several high category of explosives. Assam being a sensitive zone because of local terrorist outfit called the Ulfas, these precautions have also been taken.

Finally the bridge was made ready. Fully tested and the Prime Minister of the country himself flagged the first train on the bridge on December 25th 2018 (on the birth anniversary of his mentor, who had started this project way back in 2002, Mr Vajpayee. Unfortunately Mr Vajpayee himself was not around to see this inauguration himself.

Though some of the most amazing project management skills were used on this project, it was severely delayed due to Political short sightedness of rival parties and sheer corruption. For 10 yrs almost nothing happened and than suddenly in less than 4 yrs everything was done in record breaking speed using design and technology which the rest of the world can learn from.

However despite all work done by the BJP government, this bridge still remains the most “Time Taking” bridge till date in Indian History.